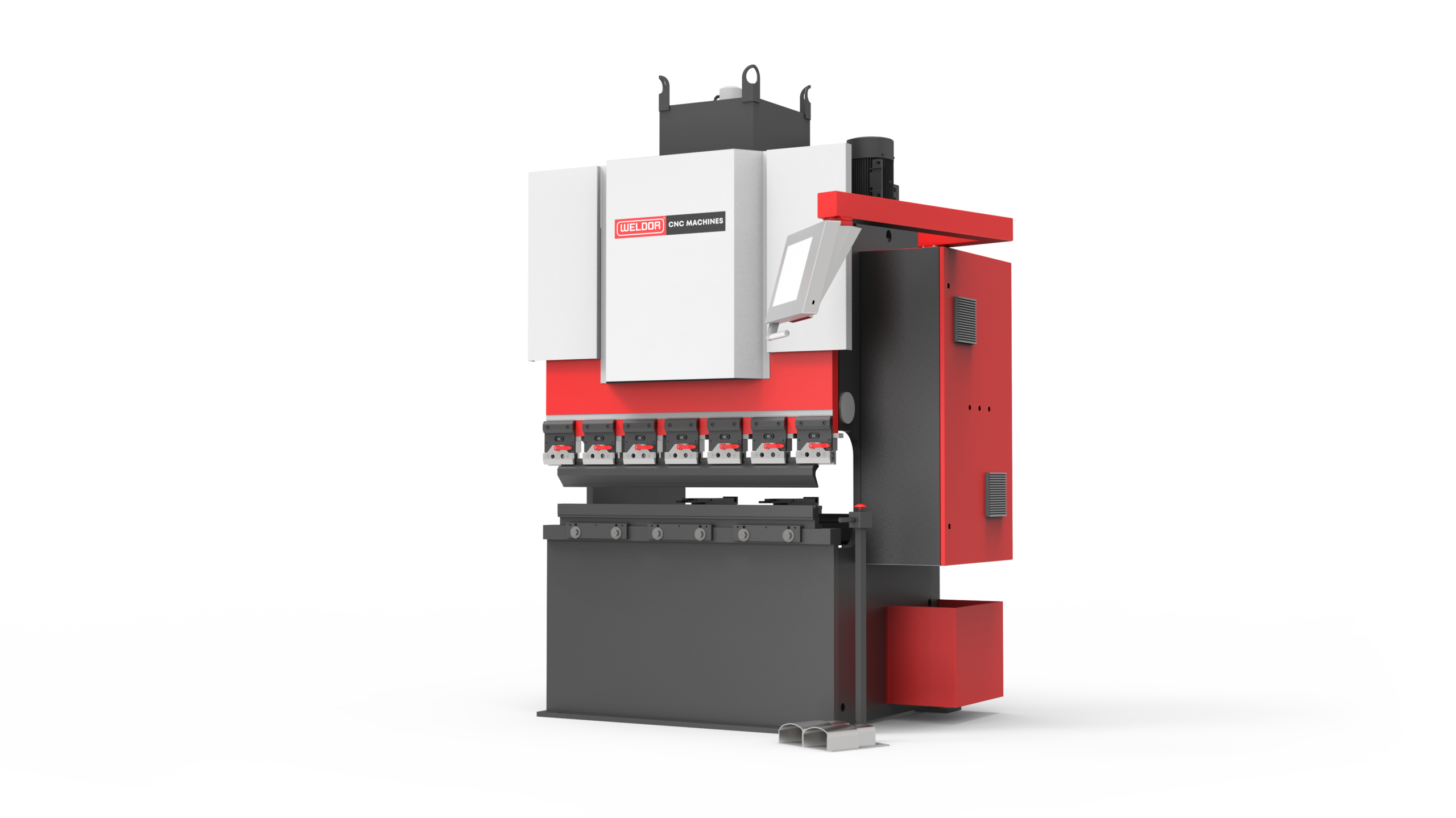

CNC Press Brakes

Compact yet powerful, the N Series’ hybrid drive system ensures fast cycle times, lower energy use, and silent operation — making it perfect for precision jobs in space-conscious environments.

- Power

- Control

- Efficiency

INTRODUCING THE N-SERIES

The N Series is Weldor’s compact CNC hybrid press brake designed for precision-focused, small-part bending. Engineered to deliver high-speed performance with a minimal footprint, it offers the perfect balance of power, control, and efficiency for workshops handling intricate components and light-gauge materials.

Smart Bending For

small parts - redefines

Introducing our N – Series Press Brake — a compact,

high-precision solution designed specifically for small-part

bending. Combining smart engineeringwith hybrid drive

technology, this machine delivers performance far beyond

conventional hydraulic models

DESIGNED FOR PRECISION.

BUILT FOR PERFORMANCE.

Equipped with a Hybrid Servo Drive System, this press

brake ensures efficient, responsive control with reduced

heat and energy loss. Ideal for electronics, enclosures,

and precision parts — it’s a small machine with big

capabilities.

Equipped with a Hybrid Servo Drive System, this press brake ensures efficient, responsive control with reduced heat and energy loss. Ideal for electronics, enclosures, and precision parts — it’s a small machine with big capabilities

Up to

70% lower

power

consumption

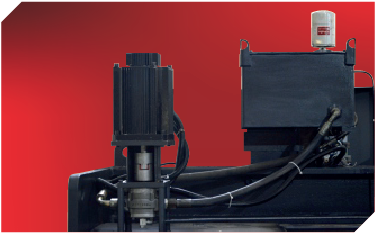

Minimal

Hydraulic

oil

usage

Fast

Accurate

bending

cycles

Near

Silent

Operation for Shop

floor comfort

Take a 360° Tour

- Rotate

- Explore

- Experience

Advantages Of N-Series

- Power

- Precision

- Efficiency

The N-Series sets a new benchmark in compact press brake technology, purpose – built for small-part bending with hybrid drive performance. With its Single

Servo System and intelligent energy management, it delivers unmatched accuracy,

space-saving design, and cost-effective operation.

SINGLE SERVO

PRECISION

Responsive, smooth

motion and consistent

bending quality

OPTIMIZED FOR

SMALL PARTS

Compact size and

tight bending accuracy

LOW ENERGY

CONSUMPTION

Hybrid drive efficiency

with idle-time

power reduction

MINIMAL

OIL USAGE

Reduces thermal load

and environmental

impact

QUIET

OPERATION

Comfortable,

low-noise workspace

for operators

LOW MAINTENANCE

DESIGN

Fewer moving parts

and simplified hydraulics

Engineered for high precision in a small footprint, the N-Series is the ideal press brake for

modern fabricators focused on agility, sustainability, and performance without

compromise.

Great Engineering Made

Smart And Productive

for You

Technical

Specifications

The N Series is available in a wide range of tonnages, bed

lengths, and axis configurations to meet diverse production

needs. From stroke length and throat depth to backgauge travel

and motor capacity, every specification is engineered for optimal precision, structural rigidity, and long-term reliability.

| Model | HBD-N | N1 | N2 | N3 | N4 |

|---|---|---|---|---|---|

| Bending Force | Ton | 25 | 25 | 30 | 40 |

| Bending Length X Thx. | mm | 1000 X 3.15 | 1250 X 2.5 | 1250 X 3 | 1250 X 4 |

| Frame Gap | mm | 1000 | 1250 | 1250 | 1250 |

| Y Approach | mm/s | 140 | 140 | 140 | 140 |

| Y Pressing | mm/s | 10 | 10 | 10 | 10 |

| Y Return | mm/s | 140 | 140 | 140 | 140 |

| Day Light | mm | 375 | 375 | 375 | 375 |

| Stroke | mm | 150 | 150 | 150 | 150 |

| Table Width | mm | 90 | 90 | 90 | 90 |

| Table Height | mm | 800 | 800 | 800 | 800 |

| Throat | mm | 200 | 200 | 200 | 200 |

| Back Gauge Finger Block | nos. | 2 | 2 | 2 | 2 |

| X-Axis Travel | mm | 500 | 500 | 500 | 500 |

| R-Axis Travel | mm | 100 | 100 | 100 | 100 |

| Peak Power | kw | 3 | 3 | 4.4 | 5 |

| Oil Tank | ltr | 35 | 35 | 35 | 35 |

| Length (L) | mm | 1500 | 1850 | 1850 | 1850 |

| Width (W) | mm | 1200 | 1200 | 1200 | 1200 |

| Height (H) | mm | 2200 | 2200 | 2200 | 2200 |

Common

Accessories

Weldor’s modular accessories enhance precision, safety, and speed—customized for your

material, geometry, and workflow. Upgrade only what you need, exactly how you need it.

CONTROLLER

OPTIONS

Weldor offers a versatile range of advanced CNC controller options to suit every level of complexity and operator preference.

CROWNING

SYSTEMS

For Press Brakes up to 100 Ton capacity and 4000 mm bending length, Slip-Type Passive Crowning offers a simple and effective natural compensation method.

BACKGAUGE

AXIS OPTIONS

The high-precision backgauge combines speed and accuracy with AC servo drives and KK guides for rapid positioning.

TOOL HOLDING

SYSTEMS

Automatic hydraulic tool alignment – upper and lower holders are hydraulically activated to align tools automatically

SAFETY

SYSTEMS

Safety interlocks in rear door and side guards provides simple operation without the need for programming by the machine operator.

Optional

Accessories

Request a Quote

Get a Fast Response

Fill in a few quick details and receive a tailored quote or product recommendation within 24 hours.

Explore other cnc press brakes

Discover our complete range of CNC press brakes tailored for diverse fabrication needs.

WITH MAIN MOTOR SERVO

WITH DUAL SERVO