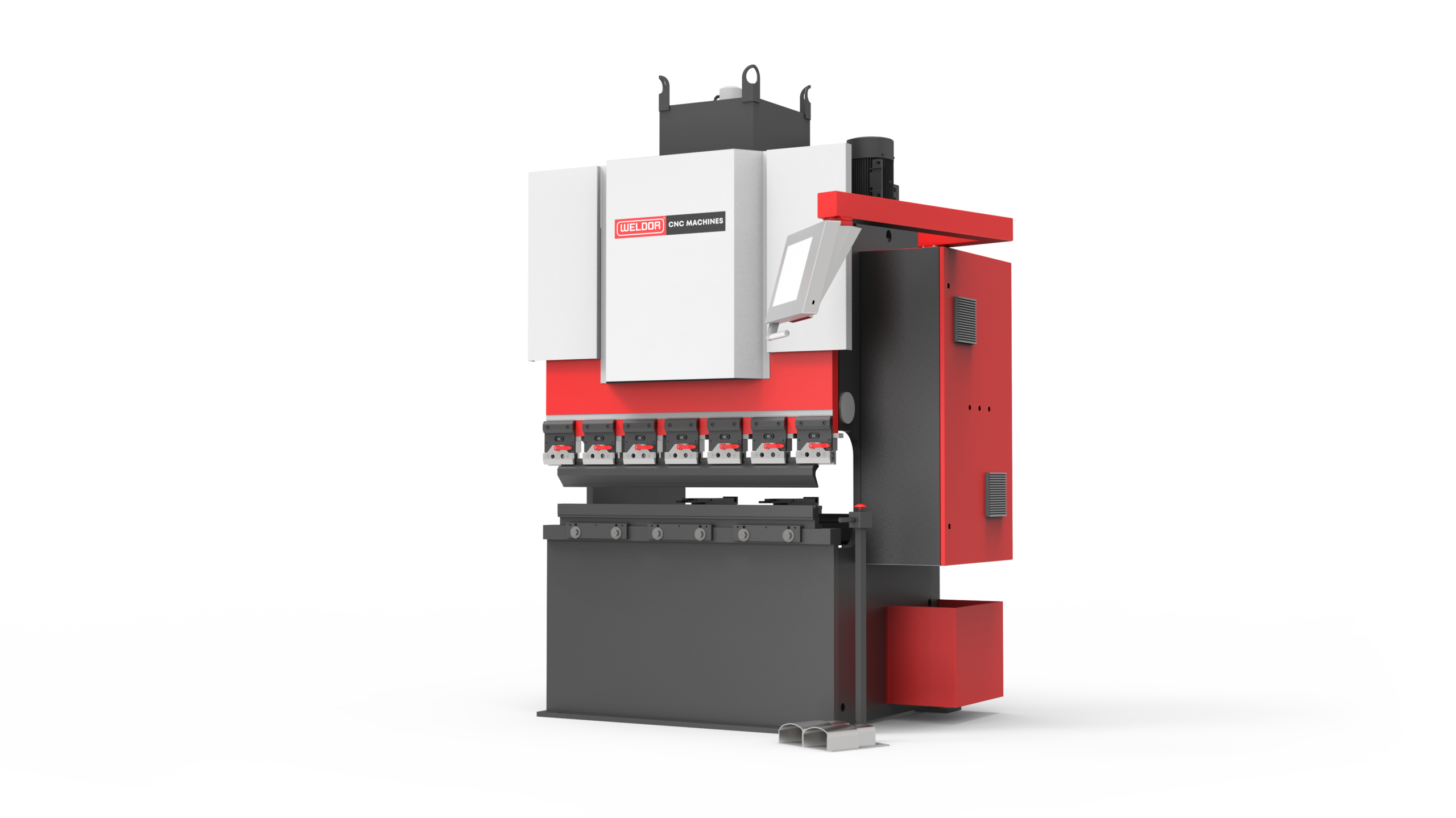

CNC Press Brakes

CNC hybrid press brake

designed for precision-focused,

small-part bending.

The MS Series represents the future of CNC Hydraulic Press Brakes combining Main Motor Servo with Hydraulic Pump

- Innovation

- Durability

- Accuracy

INTRODUCING THE MS-SERIES

The MS Series is built to offer reliable bending

performance with CNC accuracy, ideal for mediumscale fabrication needs. It combines a robust hydraulic system with intuitive

controls and essential automation features, delivering

consistent results across varied sheet metal

applications—all at a cost-effective value point.

40% Less Power Consumption

Longer Duty Cycle due to less oil heating

Reliable Bending

Accuracy

Energy Efficient

Operation

40% Faster

Cycle Time

SMART STREAMLINES SOLID.

MS Series — the next generation of CNC Hydraulic Press Brakes,

engineered for precision, efficiency, and reliability. Powered by a

Main Servo Motor, the MS Series combines the power of hydraulic

bending with the intelligent control of servo technology, offering

unmatched energy efficiency and operational stability. Whether

you are dealing with high-volume production or intricate bending

operations, the MS Series delivers consistent, repeatable results

with minimal noise and reduced maintenance.

DESIGNED FOR PRECISION.

BUILT FOR PERFORMANCE.

Its simplified design, paired with smart CNC integration,

offers an excellent balance of control, cost-efficiency,

and consistent output.

Engineered for medium to heavy-duty operations, the S-Series combines a

robust hydraulic system with a time-tested induction drive, ensuring stable

performance and low operational costs. Whether in job shops or production

lines, the S-Series is the smart choice for manufacturers looking to optimize

their workflow without compromising on reliability or accuracy.

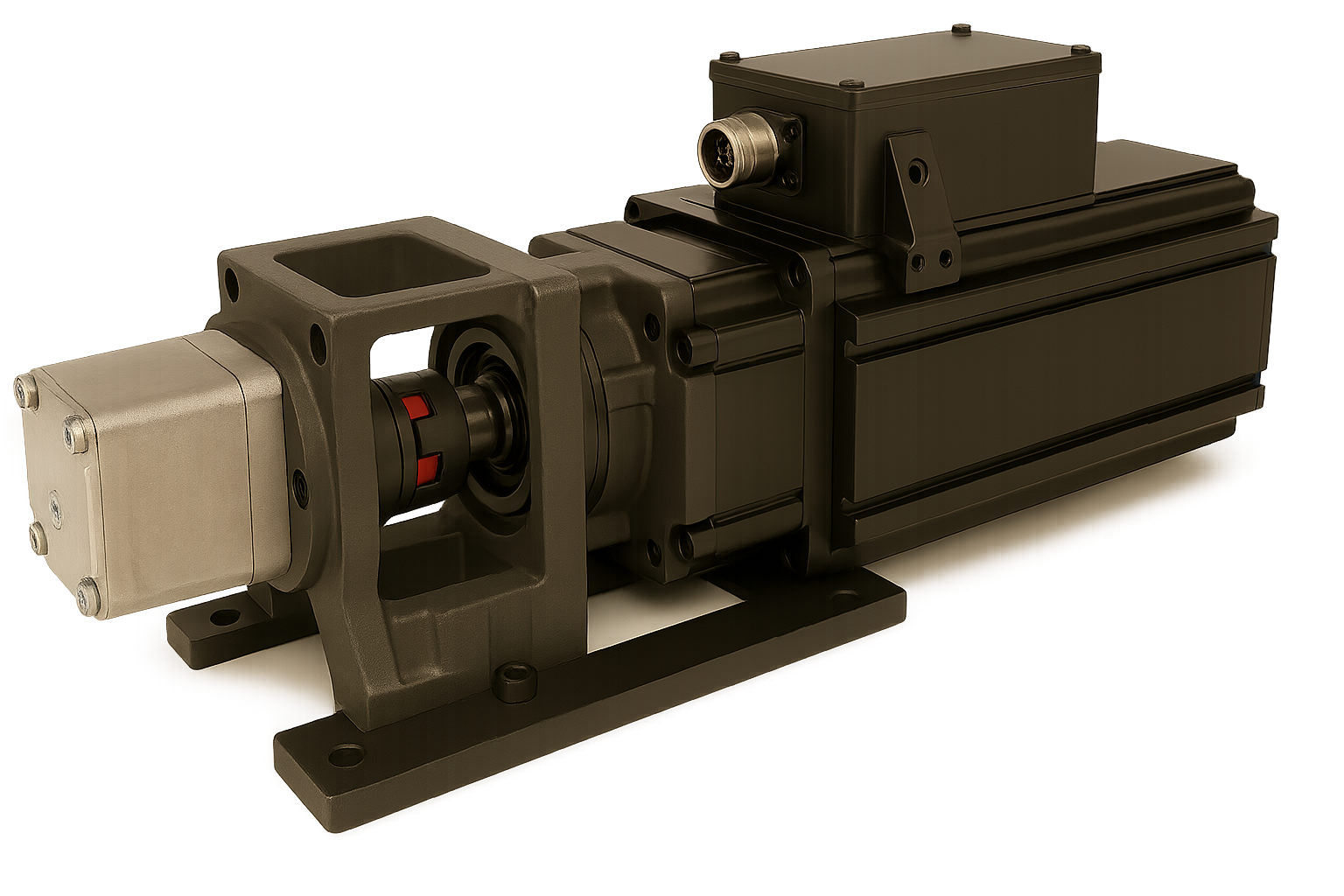

Main Servo Motor

for energy efficiency and precision control

Hydraulic Bending Power

combined with intelligent servo motion.

Reduced Operational Costs

thanks to Energy Savings up to 40% compared to the S Series.

Reduced maintenance

thanks to lower oil heating, enabled by advanced servo technology.

Consistent Performance

for both high-volume and precision tasks.

Ideal for Modern Industry Needs

meeting the demands of evolving manufacturing environments.

Take a 360° Tour

- Rotate

- Explore

- Experience

Advantages Of Ms-Series

- Precision

- Efficiency

- Performance

The MS Series represents the future of CNC Hydraulic Press Brakes, combining cutting-edge

Main Servo Motor technology with proven hydraulic power. Designed for industries that

demand high-precision bending, this machine delivers:

Superior Energy

Efficiency

with servo-driven technology

Enhanced Performance

through reduced oil heating during long cycles, ensuring better production rates

Precision Control

for accurate and repeatable results

Reduced Maintenance

thanks to fewer moving parts and intelligent servo systems

Silent

Operation

for a quieter workspace

High Productivity

for both large and intricate jobs

The MS Series is the perfect solution for companies seeking to maximize productivity while

minimizing operational costs and environmental impact.

Great Engineering Made

Smart And Productive

for You

TECHNICAL

SPECIFICATIONS

The MS Series is engineered for manufacturers looking to achieve consistent output, reduce

energy consumption, and optimize operational efficiency – all without compromising on

performance or reliability.

| Model | MS | 4015 | 5020 | 6502 | 6525 | 8025 | 8030 | 1025 |

|---|---|---|---|---|---|---|---|---|

| Tonnage | Ton | 40 | 50 | 65 | 65 | 80 | 80 | 100 |

| Bending Length X Thk. | mm | 1500 x 3.15 | 2050 x 3 | 2050 x 4 | 2500 x 3 | 2500 x 4 | 3100 x 3 | 2500 x 5 |

| Distance Between Housing | mm | 1050 | 1550 | 1550 | 2050 | 2050 | 2550 | 2050 |

| Y Rapid Speed | mm/s | 140 | 140 | 140 | 140 | 140 | 140 | 140 |

| Y Working Speed | mm/s | 10 | 10 | 10 | 10 | 10 | 10 | 10 |

| Y Return Speed | mm/s | 140 | 140 | 140 | 140 | 140 | 140 | 140 |

| Day Light | mm | 375 | 375 | 375 | 375 | 375 | 375 | 375 |

| Table Width | mm | 90 | 90 | 90 | 90 | 60 | 60 | 60 |

| Table Height | mm | 800 | 800 | 800 | 800 | 900 | 900 | 900 |

| Stroke | mm | 150 | 150 | 150 | 150 | 150 | 150 | 150 |

| Throat Depth | mm | 300 | 300 | 300 | 300 | 300 | 300 | 300 |

| Back Gauge Finger Block | nos. | 2 | 2 | 2 | 2 | 2 | 2 | 2 |

| Travel in X Axis | mm | 500 | 500 | 500 | 500 | 600 | 600 | 600 |

| Travel in R Axis | mm(+/-) | 100 | 100 | 100 | 100 | 100 | 100 | 100 |

| Motor Power | kW | 10 kW | 10 kW | 10 kW | 10 kW | 14 kW | 14 kW | 14 kW |

| Oil Tank Capacity | ltr | 320 | 320 | 320 | 320 | 450 | 450 | 450 |

| Length (L) | mm | 1750 | 2500 | 2500 | 3000 | 3100 | 3500 | 3000 |

| Width (W) | mm | 1200 | 1300 | 1300 | 1300 | 1350 | 1400 | 1500 |

| Height (H) | mm | 2350 | 2400 | 2400 | 2400 | 2450 | 2450 | 2600 |

| Model | MS | 1003 | 1004 | 1325 | 1303 | 1304 | 1625 | 1603 |

|---|---|---|---|---|---|---|---|---|

| Tonnage | Ton | 100 | 100 | 130 | 130 | 130 | 160 | 160 |

| Bending Length X Thk. | mm | 3100 x 4 | 4000 x 3 | 2500 x 6 | 3100 x 5 | 4000 x 4 | 2500 x 8 | 3100 x 6 |

| Distance Between Housing | mm | 2550 | 3400 | 2050 | 2550 | 3400 | 2050 | 2550 |

| Y Rapid Speed | mm/s | 140 | 140 | 140 | 140 | 140 | 140 | 140 |

| Y Working Speed | mm/s | 10 | 10 | 10 | 10 | 10 | 10 | 10 |

| Y Return Speed | mm/s | 140 | 140 | 140 | 140 | 140 | 140 | 140 |

| Day Light | mm | 375 | 375 | 375 | 375 | 375 | 400 | 400 |

| Table Width | mm | 60 | 60 | 90 | 90 | 90 | 90 | 90 |

| Table Height | mm | 900 | 900 | 965 | 965 | 965 | 965 | 965 |

| Stroke | mm | 150 | 150 | 175 | 150 | 175 | 175 | 175 |

| Throat Depth | mm | 300 | 300 | 300 | 300 | 300 | 300 | 300 |

| Back Gauge Finger Block | nos. | 2 | 2 | 2 | 2 | 2 | 2 | 2 |

| Travel in X Axis | mm | 600 | 600 | 600 | 600 | 600 | 600 | 600 |

| Travel in R Axis | mm(+/-) | 100 | 100 | 100 | 100 | 100 | 100 | 100 |

| Motor Power | kW | 14 kW | 14 kW | 15 kW | 15 kW | 15 kW | 18 kW | 18 kW |

| Oil Tank Capacity | ltr | 450 | 450 | 450 | 500 | 450 | 450 | 450 |

| Length (L) | mm | 3550 | 4500 | 3100 | 3500 | 4500 | 3150 | 3750 |

| Width (W) | mm | 1500 | 1500 | 1600 | 1600 | 1600 | 1700 | 1700 |

| Height (H) | mm | 2600 | 2600 | 2750 | 2750 | 2750 | 2800 | 2800 |

| Model | MS | 2504 | 2505 | 2506 | 3253 | 3254 | 3255 | 3256 |

|---|---|---|---|---|---|---|---|---|

| Tonnage | Ton | 250 | 250 | 250 | 325 | 325 | 325 | 325 |

| Bending Length X Thk. | mm | 4000 X 8 | 5000 X 6 | 6000 X 5 | 3100 x 13 | 4000 x 10 | 5000 x 8 | 6000 x 6 |

| Distance Between Housing | mm | 3400 | 4000 | 5000 | 2550 | 3400 | 4000 | 5000 |

| Y Rapid Speed | mm/s | 140 | 140 | 140 | 140 | 140 | 140 | 140 |

| Y Working Speed | mm/s | 8 | 8 | 8 | 8 | 8 | 8 | 8 |

| Y Return Speed | mm/s | 120 | 120 | 120 | 100 | 100 | 100 | 100 |

| Day Light | mm | 500 | 500 | 500 | 500 | 500 | 500 | 500 |

| Table Width | mm | 120 | 120 | 120 | 150 | 150 | 150 | 150 |

| Table Height | mm | 965 | 965 | 965 | 965 | 1000 | 1000 | 1000 |

| Stroke | mm | 250 | 250 | 300 | 250 | 250 | 250 | 250 |

| Throat Depth | mm | 300 | 300 | 300 | 300 | 300 | 300 | 300 |

| Back Gauge Finger Block | nos. | 3 | 3 | 4 | 2 | 3 | 3 | 4 |

| Travel in X-Axis | mm | 700 | 700 | 700 | 700 | 700 | 700 | 700 |

| Travel in R-Axis | mm(+/-) | 120 | 120 | 120 | 120 | 120 | 120 | 120 |

| Motor Power | kW | 30 kW | 30 kW | 30 kW | 35 kW | 35 kW | 35 kW | 35 kW |

| Oil Tank Capacity | ltr | 650 | 650 | 650 | 650 | 650 | 650 | 650 |

| Length (L) | mm | 4800 | 5850 | 6800 | 3800 | 4800 | 5800 | 6800 |

| Width (W) | mm | 1800 | 1800 | 1800 | 1850 | 1850 | 1850 | 1850 |

| Height (H) | mm | 3100 | 3100 | 3100 | 3150 | 3150 | 3150 | 3150 |

| Model | MS | 4253 | 4254 | 4255 | 4256 |

|---|---|---|---|---|---|

| Tonnage | Ton | 425 | 425 | 425 | 425 |

| Bending Length X Thk. | mm | 3100 X 17.5 | 4000 x 13 | 5000 x 10 | 6000 x 8 |

| Distance Between Housing | mm | 2550 | 3400 | 4000 | 5000 |

| Y Rapid Speed | mm/s | 140 | 140 | 140 | 140 |

| Y Working Speed | mm/s | 8 | 8 | 8 | 8 |

| Y Return Speed | mm/s | 100 | 100 | 100 | 100 |

| Day Light | mm | 550 | 550 | 550 | 550 |

| Table Width | mm | 200 | 200 | 200 | 200 |

| Table Height | mm | 1100 | 1100 | 1100 | 1100 |

| Stroke | mm | 300 | 300 | 300 | 300 |

| Throat Depth | mm | 325 | 325 | 325 | 325 |

| Back Gauge Finger Block | nos. | 2 | 3 | 3 | 4 |

| Travel in X- Axis | mm | 700 | 700 | 700 | 700 |

| Travel in R- Axis | mm(+/-) | 120 | 120 | 120 | 120 |

| Motor Power | kW | 40 kW | 40 kW | 40 kW | 40 kW |

| Oil Tank Capacity | ltr | 650 | 650 | 650 | 650 |

| Length (L) | mm | 3850 | 4850 | 5550 | 6850 |

| Width (W) | mm | 2100 | 2100 | 2100 | 2100 |

| Height (H) | mm | 3200 | 3200 | 3200 | 3200 |

Common

Accessories

Weldor’s modular accessories enhance precision, safety, and speed—customized for your

material, geometry, and workflow. Upgrade only what you need, exactly how you need it.

CONTROLLER

OPTIONS

Weldor offers a versatile range of advanced CNC controller options to suit every level of complexity and operator preference.

CROWNING

SYSTEMS

For Press Brakes up to 100 Ton capacity and 4000 mm bending length, Slip-Type Passive Crowning offers a simple and effective natural compensation method.

BACKGAUGE

AXIS OPTIONS

The high-precision backgauge combines speed and accuracy with AC servo drives and KK guides for rapid positioning.

TOOL HOLDING

SYSTEMS

Automatic hydraulic tool alignment – upper and lower holders are hydraulically activated to align tools automatically

SAFETY

SYSTEMS

Safety interlocks in rear door and side guards provides simple operation without the need for programming by the machine operator.

Optional

Accessories

Request a Quote

Get a Fast Response

Fill in a few quick details and receive a tailored quote or product recommendation within 24 hours.

Explore other cnc press brakes

Discover our complete range of CNC press brakes tailored for diverse fabrication needs.

WITH MAIN MOTOR SERVO

WITH DUAL SERVO