Infrastructure &

Manufacturing Excellence

- innovation

- integration

- Impact

Infrastructure

World-Class Infrastructure Where Innovation Meets Precision

This ensures unmatched quality and precision across all products.

Manufacturing Excellence

Where Precision

Meet Scale

Assembly Shop

8000 Sq.ft

streamlined

machine assembly.

Machine Shop

9000 Sq. ft.

precision machining.

Fabrication Shop

8500 Sq. ft.

Why Weldor CNC Machines Limited

The Power Behind

Precision Engineering

Capacity OverView

Production of Large Frames & Components

CNC and DRO Floor Boring

Machines handle massive

workpieces up to 8,000 mm with

high precision.

Machining Complex Geometries

Bed and Plano Milling Machines

ensure flexibility in intricate

machining, reducing outsourcing

needs.

Batch & Custom Manufacturing

A versatile machine mix supports

both high-volume batch

production and specialized

one-off manufacturing

MACHINING CAPACITY

precision and efficiency in handling complex, heavy components:

NC FLOOR BORING MACHINE

(GIDDINGS & LEWIS – USA)

Work Envelope: 6000 × 3000 × 1700 mm High-precision machining with NC functionality for automation and repeatability.

DRO FLOOR BORING MACHINE

(RESTELLINI – ITALY)

Work Envelope: 8000 × 1700 × 700 mm Ideal for long components with manual assistance and Digital Readout (DRO) for moderate precision.

NC BED MILLING MACHINE

(MECOF – ITALY)

Work Envelope: 6700 × 1700 × 1050 mm Combines numerical control with bed milling for accurate machining of large, flat components.

PLANI-MILLER

(HUDDERSFIELD – UK)

Work Envelope: 4000 × 1500 × 1050 mm Provides high stability for milling large workpieces in heavy-duty operations.

PLANNER

Work Envelope: 3000 × 1200 × 500 mm

Ideal for machining flat surfaces on small to medium-sized components.

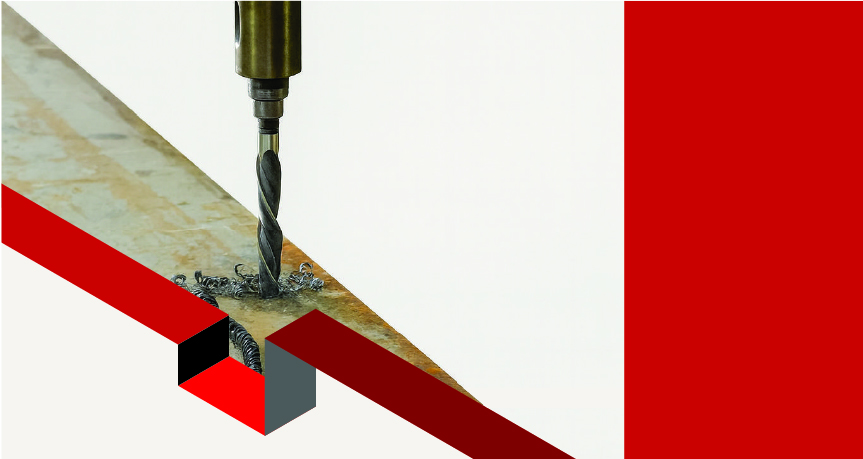

RADIAL DRILLING MACHINES

Handles versatile drilling operations with varying sizes (63 mm and 30 mm).

Ensures quick and efficient hole-making for both large and small components

TURNING CAPACITY

LATHE MACHINES

[4.5' / 6' / 20']

Handles small to very large

components with high accuracy.

Ideal for machining shafts, cylinders, and other rotational parts.

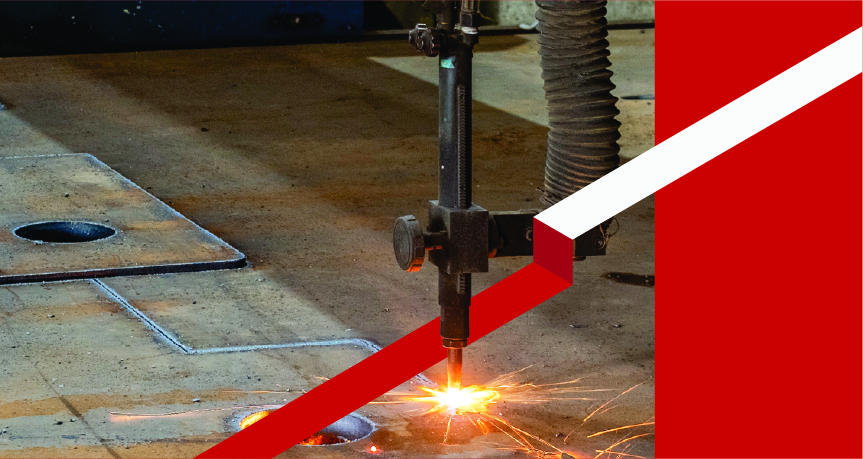

FABRICATION & CUTTING CAPACITY

CNC FLAME CUTTING MACHINE

Cutting Area: 6200 × 3000 mm

Cutting Thickness: Up to 150 mm (Mild Steel)

Enables high-speed, precision cutting of thick metal sheets for industrial application

HYDRAULIC SHEARING MACHINE

Capacity: 3100 × 10 mm (Variable Rake Angle)

Designed for cutting oil tank plates and general-purpose sheet metal fabrication.

HYDRAULIC PRESS

(300 Ton, 150 Ton – WELDOR, India)

Essential for forming, bending, and shaping metal components with high precision.

STRESS-RELIEF CAPACITY

Vibratory Stress Relieving Machine reduces residual stresses in machined and welded components.

Enhances dimensional stability and overall performance.

ADDITIONAL CAPACITY

Conventional Shaper Machine used for small-scale shaping and finishing tasks.

OVERALL MANUFACTURING CAPACITY

The unit’s advanced infrastructure enables :

Fabrication & Machining of large-scale components efficiently.

High-Precision Operations with both manual and NC capabilities.

End-to-End Manufacturing including cutting, machining, forming, and stress relief.

MACHINING & FABRICATION SHOP

CNC FLOOR BORING MACHINE

6000 × 3000 × 1700 mm

Giddings & Lewis, USA

PLANNER

3000 × 1200 × 500 mm

LATHE MACHINE

6000 mm (20’)

CNC FLAME CUTTING

9200 × 3000 mm - Cutting Thickness: Up to - 150 mm (Mild Steel)

DRO FLOOR BORING MACHINE

8000 × 1700 × 700 mm Restellini, Italy

LATHE MACHINE

1350 mm (4.5’)

CONVENTIONAL SHAPER

MACHINE

VIBRATORY STRESS RELIEVING MACHINE

NC BED MILLING MACHINE

6700 × 1700 × 1050 mm Mecof, Italy

LATHE MACHINE

2100 mm (6’)

CNC FLAME CUTTING

6200 × 3000 mm Cutting Thickness: Up to 150 mm (Mild Steel)

HYDRAULIC PRESS

300 Ton Weldor, India

PLANO-MILLER

4000 × 1500 × 1050 mm Huddersfield, UK

Design & Simulation Capabilities

Advanced Design Capabilities With 2D & 3D CAD Software

ADVANCED DESIGN CAPABILITIES

WITH FEA FOR PRECISION ENGINEERING

Flame Cutting & Straightening

High Precesion CNC Flame Cutting With Nesting Optimization

HYDRAULIC PLATE STRAIGHTENING

FOR STRUCTURAL ACCURACY

Fabrication & Stress Relieving

Heavy-Duty Fabrication

Built to Endure

SKILLED WELDING FOR INTEGRITY

VIBRATORY STRESS RELIEVING

FOR ENHANCED STABILITY

Advance Drilling Machining

Precision Drilling & Machining

For Complex Components

Radial Drilling Machines

03 Nos.

25 mm, 32 mm & 60 mm

Vertical Machining Center(VMC)

1000X500 mm

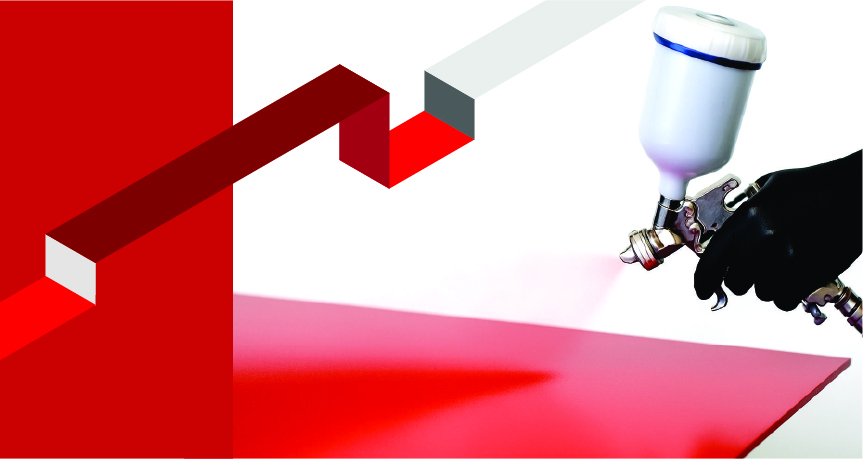

Paint Process

Multi-Step Painting

Process for Superior finish

Surface

Preparation

The plates are thoroughly hand-ground using highquality hand grinders to remove any imperfections and prepare the surface for fabrication

Primer

Application

Once the machining is complete, the entire machine is coated with a highperformance Red Oxide primer. This serves as a corrosionresistan base, ensuring longevity and resilience

Putty

Layering

Two layers of putty are carefully applied, providing a smooth and even surface. After application, the putty is washed off with water to achieve a refined finish.

Final

Coating

The machine is then painted with premium Polyurethane paints, developed specifically for Weldor CNC Machines. Available in Signal Red, Chassis Grey, & Silver, these coatings are powered by advanced American powder color technology.

CUSTOMIZATION OPTION

This comprehensive paint process ensures that every Weldor CNC machine stands out in both performance and appearance, providing a long-lasting, robust finish that meets the highest standards in the industry.

Inspection & Testing

Where Quality

Meets Assurance

Dry Run Testing

Each machine undergoes a comprehensive dry run for a continuous 8-hour shift, nonstop. This extended operation helps us identify potential issues such as overheating, leakages, inaccuracies in repeatability, and other critical factors that could impact performance.

Full Load Trials

Following the dry run, the machine undergoes full load trials, simulating realworld operational conditions. This allows us to assess the machine's performance under maximum capacity, ensuring that it operates smoothly, efficiently, and without issues during heavy-duty use.

Pre-Dispatch Inspection (PDI)

After the dry run and full load trials, a detailed Pre-Dispatch Inspection (PDI) report is generated. This report thoroughly evaluates the machine against our stringent quality standards to confirm whether it qualifies for dispatch. Only machines that meet these exacting standards are cleared for delivery.

CHECKING PARAMETER

- Request a Quote

- Get a Fast Response