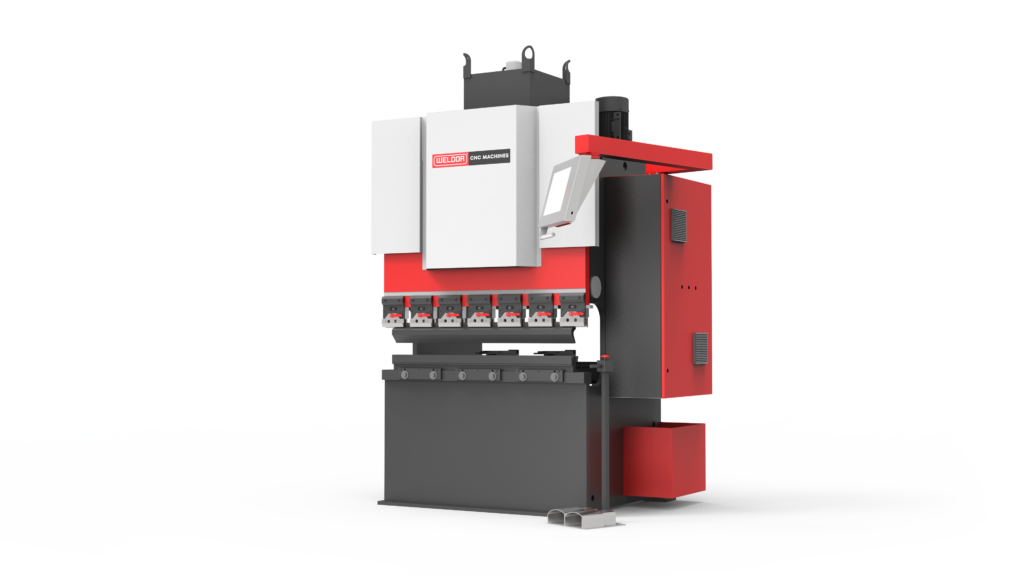

CNC Press Brakes

A versatile workhorse, the S Series offers reliable CNC hydraulic performance across a wide tonnage range. With multiple backgauge axis options and rugged construction, it’s designed for flexibility in batch and custom fabrication.

- Precision

- Strength

- Performance

INTRODUCING THE N-SERIES

Standardized

Models

Fast Delivery

Customizable

Economical

Ranges: 40 Ton -

2000 Ton

Multiple Backgauge Axis

Available with trusted controller options like Cybelec CybTouch or VisiTouch, the S Series simplifies even

complex bending tasks through intuitive programming, angle correction, and visual step guidance.

This combination of rugged hardware and digital intelligence ensures faster setups, fewer reworks, and

increased operator productivity.

Made For Everyday excellence

The S-Series CNC Hydraulic Press Brake is designed to deliver dependable bending performance with a focus on long-term value and cost-efficiency. Powered by a high-efficiency induction motor and controlled via advanced

CNC technology, the S-Series offers the perfect balance of precision, durability, and affordability for a wide range of fabrication needs.

ADVANTAGES OF THE

STRENGTH. STABILITY. VALUE.

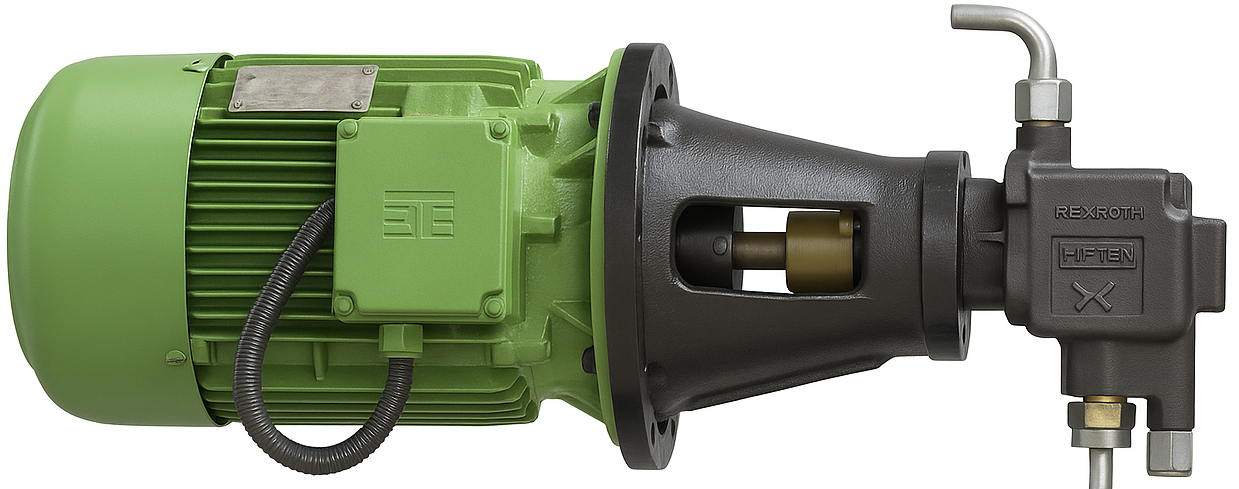

Robust Induction

Motor Drive

Proven 3-phase induction motor delivers dependable performance with minimal downtime.

Powerful Hydraulic Bending System

Delivers consistent and precise force output, even in heavy-duty applications, thanks to a closed-loop servo valve-controlled hydraulic power pack.

Economical

Operation

Cost-effective solution with low energy consumption and high durability — ideal for budget-conscious production.

Low Maintenance

Requirements

Fewer electronic components and rugged mechanical design reduce maintenance time and costs.

Stable Performance

Under Load

Reliable operation in demanding production environments, from batch jobs to custom fabrication.

Optimized for General

Industrial Use

A versatile, durable press brake that meets the core demands of modern manufacturing with a focus on long-term ROI.

Take a 360° Tour

- Rotate

- Explore

- Experience

Great Engineering Made

Smart And Productive

for You

Advantages Of s-Series

- Strength

- Stability

- Value

Industrial-Grade

Reliability

with durable induction motor drive

Consistent Bending

Accuracy

supported by closed-loop hydraulic control

Cost-Efficient Operation

with low investment costs and minimal maintenance, offering long-term reliability at a competitive price point.

Low Maintenance

Requirements

thanks to simplified mechanical systems and fewer sensitive components

Stable, Continuous

Performance

even during extended production runs

Versatile

Productivity

ideal for general fabrication, batch production, and heavy-duty applications

Great Engineering Made

Accurate for You

TECHNICAL

SPECIFICATIONS

| Model | WCMPB | S1 | S2 | S3 | S4 | S5 | S6 | S7 | S8 | S9 |

|---|---|---|---|---|---|---|---|---|---|---|

| Tonnage | Ton | 40 | 50 | 65 | 65 | 80 | 80 | 100 | 100 | 100 |

| Bending Length × Thx. | mm | 1500 × 3.15 | 2050 × 3 | 2050 × 4 | 2500 × 3 | 2500 × 4 | 3100 × 3 | 2500 × 5 | 3100 × 4 | 4000 × 3 |

| Distance Between Housing | mm | 1050 | 1550 | 1550 | 2050 | 2050 | 2550 | 2050 | 2550 | 3400 |

| Y Rapid Speed | mm/sec | 100 | 100 | 100 | 100 | 100 | 100 | 100 | 100 | 100 |

| Y Working Speed | mm/sec | 8 | 8 | 8 | 8 | 10 | 10 | 10 | 10 | 10 |

| Y Return Speed | mm/sec | 80 | 80 | 80 | 80 | 60 | 60 | 60 | 60 | 60 |

| Day Light | mm | 375 | 375 | 375 | 375 | 375 | 375 | 375 | 375 | 375 |

| Table Width | mm | 90 | 90 | 90 | 90 | 60 | 60 | 60 | 60 | 60 |

| Table Height | mm | 800 | 800 | 800 | 800 | 900 | 900 | 900 | 900 | 900 |

| Stroke | mm | 150 | 150 | 150 | 150 | 150 | 150 | 150 | 150 | 150 |

| Throat Depth | mm | 300 | 300 | 300 | 300 | 300 | 300 | 300 | 300 | 300 |

| Back Gauge Finger Block | nos. | 2 | 2 | 2 | 2 | 2 | 2 | 2 | 2 | 2 |

| Travel In X Axis | mm | 500 | 500 | 500 | 500 | 600 | 600 | 600 | 600 | 600 |

| Travel In R Axis | mm +/- | 100 | 100 | 100 | 100 | 100 | 100 | 100 | 100 | 100 |

| Motor Power | hp/kW | 5 / 3.7 | 7.5 / 5.5 | 7.5 / 5 | 7.5 / 5 | 10 / 7.5 | 10 / 7.5 | 10 / 7.5 | 10 / 7.5 | 10 / 7.5 |

| Oil Tank Capacity | ltr | 300 | 300 | 300 | 300 | 450 | 450 | 450 | 450 | 450 |

| Length | mm | 1750 | 2500 | 2500 | 3000 | 3100 | 3500 | 3000 | 3500 | 4500 |

| Width | mm | 1200 | 1300 | 1300 | 1300 | 1350 | 1400 | 1500 | 1500 | 1500 |

| Height | mm | 2350 | 2400 | 2400 | 2400 | 2450 | 2450 | 2600 | 2450 | 2600 |

| Model | WCMPB | S10 | S11 | S12 | S13 | S14 | S15 | S16 | S17 | S18 |

|---|---|---|---|---|---|---|---|---|---|---|

| Tonnage | Ton | 130 | 130 | 130 | 160 | 160 | 160 | 200 | 200 | 200 |

| Bending Length X Thx. | mm | 2500 × 6 | 3100 × 5 | 4000 × 4 | 2500 × 8 | 3100 × 6 | 4000 × 5 | 2500 × 10 | 3100 × 8 | 4000 × 6 |

| Distance Between Housing | mm | 2050 | 2550 | 3400 | 2050 | 2550 | 3400 | 2050 | 2550 | 3400 |

| Y Rapid Speed | mm/sec | 100 | 100 | 100 | 100 | 100 | 100 | 70 | 70 | 70 |

| Y Working Speed | mm/sec | 10 | 10 | 10 | 8 | 8 | 8 | 8 | 8 | 8 |

| Y Return Speed | mm/sec | 60 | 60 | 60 | 70 | 70 | 60 | 50 | 50 | 50 |

| Day Light | mm | 375 | 375 | 375 | 400 | 400 | 400 | 475 | 475 | 475 |

| Table Width | mm | 90 | 90 | 90 | 90 | 90 | 90 | 90 | 90 | 90 |

| Table Height | mm | 965 | 965 | 965 | 965 | 965 | 965 | 965 | 965 | 965 |

| Stroke | mm | 175 | 150 | 175 | 175 | 175 | 175 | 250 | 225 | 225 |

| Throat Depth | mm | 300 | 300 | 300 | 300 | 300 | 300 | 300 | 300 | 300 |

| Back Gauge Finger Block | nos. | 2 | 2 | 2 | 2 | 2 | 2 | 2 | 2 | 2 |

| Travel In X Axis | mm | 600 | 600 | 600 | 600 | 600 | 600 | 600 | 600 | 600 |

| Travel In R Axis | mm(+/-) | 100 | 100 | 100 | 100 | 100 | 100 | 100 | 100 | 100 |

| Motor Power | hp/kw | 12.5/9 | 12/9 | 12.5/9 | 15/11.2 | 15/11.2 | 15/11.2 | 20/15 | 20/15 | 20/15 |

| Oil Tank Capacity | ltr | 450 | 500 | 450 | 450 | 500 | 500 | 450 | 500 | 550 |

| Length (L) | mm | 3100 | 3700 | 4500 | 3150 | 3500 | 4500 | 3150 | 3500 | 4500 |

| Width (W) | mm | 1600 | 1600 | 1600 | 1650 | 1650 | 1650 | 1800 | 1800 | 1800 |

| Height (H) | mm | 2750 | 2600 | 2750 | 2800 | 2700 | 2700 | 3050 | 2700 | 2700 |

| Model | WCMPB | S19 | S20 | S21 | S22 | S23 | S24 | S25 | S26 |

|---|---|---|---|---|---|---|---|---|---|

| Tonnage | Ton | 200 | 200 | 250 | 250 | 250 | 250 | 325 | 325 |

| Bending Length X Thx. | mm | 5000 X 5 | 6000 X 4 | 3100 X 10 | 4000 X 8 | 5000 X 6 | 6000 X 5 | 3100 X 13 | 4000 X 10 |

| Distance Between Housing | mm | 4000 | 5000 | 2550 | 3400 | 4000 | 5000 | 2550 | 3400 |

| Y Rapid Speed | mm/sec | 70 | 70 | 70 | 70 | 70 | 70 | 60 | 60 |

| Y Working Speed | mm/sec | 8 | 8 | 8 | 8 | 8 | 8 | 8 | 8 |

| Y Return Speed | mm/sec | 50 | 50 | 50 | 50 | 50 | 50 | 50 | 50 |

| Day Light | mm | 475 | 475 | 500 | 500 | 500 | 500 | 500 | 500 |

| Table Width | mm | 90 | 90 | 90 | 120 | 120 | 120 | 150 | 150 |

| Table Height | mm | 965 | 965 | 965 | 965 | 965 | 965 | 965 | 1000 |

| Stroke | mm | 225 | 225 | 225 | 250 | 300 | 300 | 250 | 250 |

| Throat Depth | mm | 300 | 300 | 300 | 300 | 300 | 300 | 300 | 300 |

| Back Gauge Finger Block | nos. | 2 | 4 | 2 | 3 | 3 | 4 | 2 | 3 |

| Travel In X Axis | mm | 600 | 600 | 700 | 700 | 700 | 700 | 700 | 700 |

| Travel In R Axis | mm(+/-) | 100 | 100 | 120 | 120 | 120 | 120 | 120 | 120 |

| Motor Power | hp/kw | 20/15 | 20/15 | 25/18.75 | 25/18.75 | 25/18.75 | 25/18.75 | 40/30 | 40/30 |

| Oil Tank Capacity | ltr | 600 | 600 | 600 | 600 | 600 | 600 | 650 | 650 |

| Length (L) | mm | 5500 | 6500 | 3500 | 4500 | 5500 | 6500 | 3800 | 4800 |

| Width (W) | mm | 1800 | 1800 | 1850 | 1850 | 1850 | 1850 | 1850 | 1850 |

| Height (H) | mm | 2700 | 2700 | 2800 | 2800 | 2800 | 2800 | 2900 | 2900 |

| Model | WCMPB | S27 | S28 | S29 | S30 | S31 | S32 | S33 | S34 |

|---|---|---|---|---|---|---|---|---|---|

| Tonnage | Ton | 325 | 325 | 425 | 425 | 425 | 425 | 600 | 600 |

| Bending Length X Thx. | mm | 5000 X 8 | 6000 X 6 | 3100 X 17.5 | 4000 X 13 | 5000 X 10 | 6000 X 8 | 4000 X 18 | 5000 X 15 |

| Distance Between Housing | mm | 4000 | 5000 | 2550 | 3400 | 4000 | 5000 | 3400 | 4000 |

| Y Rapid Speed | mm/sec | 60 | 60 | 50 | 50 | 50 | 50 | 50 | 50 |

| Y Working Speed | mm/sec | 8 | 8 | 7 | 7 | 7 | 7 | 6 | 6 |

| Y Return Speed | mm/sec | 50 | 50 | 50 | 50 | 50 | 50 | 40 | 40 |

| Day Light | mm | 500 | 500 | 550 | 550 | 550 | 550 | 625 | 625 |

| Table Width | mm | 150 | 150 | 200 | 200 | 200 | 200 | 250 | 250 |

| Table Height | mm | 1000 | 1000 | 1100 | 1100 | 1100 | 1100 | 1200 | 1200 |

| Stroke | mm | 250 | 250 | 300 | 300 | 300 | 300 | 325 | 325 |

| Throat Depth | mm | 300 | 300 | 325 | 325 | 325 | 325 | 325 | 325 |

| Back Gauge Finger Block | nos. | 3 | 3 | 4 | 4 | 3 | 4 | 3 | 3 |

| Travel In X Axis | mm | 700 | 700 | 700 | 700 | 700 | 700 | 700 | 700 |

| Travel In R Axis | mm(+/-) | 120 | 120 | 120 | 120 | 120 | 120 | 120 | 120 |

| Motor Power | hp/kw | 40 / 30 | 40 / 30 | 50/37.5 | 50/37.5 | 50/37.5 | 50/37.5 | 60/45 | 60/45 |

| Oil Tank Capacity | ltr | 650 | 650 | 700 | 700 | 700 | 700 | 800 | 800 |

| Length (L) | mm | 5800 | 6800 | 3850 | 4850 | 5550 | 6850 | 4900 | 5900 |

| Width (W) | mm | 1850 | 1850 | 2100 | 2100 | 2100 | 2100 | 2300 | 2300 |

| Height (H) | mm | 2900 | 2900 | 3000 | 3000 | 3000 | 3000 | 3200 | 3200 |

| Model | WCMPB | S35 | S36 | S37 | S38 | S39 | S40 |

|---|---|---|---|---|---|---|---|

| Tonnage | Ton | 600 | 600 | 800 | 800 | 800 | 800 |

| Bending Length X Thx. | mm | 6000 X 12.5 | 8000 X 9 mm | 5000 X 20 | 6000 X 16 | 8000 X 12.5 | 9100 X 10 |

| Distance Between Housing | mm | 5000 | 7000 | 4000 | 5000 | 7000 | 8000 |

| Y Rapid Speed | mm/sec | 50 | 50 | 50 | 50 | 50 | 50 |

| Y Working Speed | mm/sec | 6 | 6 | 5 | 5 | 5 | 5 |

| Y Return Speed | mm/sec | 40 | 40 | 40 | 40 | 40 | 40 |

| Day Light | mm | 625 | 625 | 625 | 625 | 625 | 625 |

| Table Width | mm | 250 | 250 | 250 | 250 | 250 | 250 |

| Table Height | mm | 1250 | 1250 | 1250 | 1250 | 1250 | 1250 |

| Stroke | mm | 325 | 325 | 325 | 325 | 325 | 325 |

| Throat Depth | mm | 325 | 325 | 325 | 325 | 325 | 325 |

| Back Gauge Finger Block | nos. | 4 | 4 | 4 | 4 | 4 | 4 |

| Travel In X Axis | mm | 700 | 700 | 700 | 700 | 700 | 700 |

| Travel In R Axis | mm(+/-) | 120 | 120 | 120 | 120 | 120 | 120 |

| Motor Power | hp/kw | 60/45 | 60/45 | 60/45 | 60/45 | 60/45 | 60/45 |

| Oil Tank Capacity | ltr | 800 | 800 | 1000 | 1000 | 1000 | 1000 |

| Length (L) | mm | 6900 | 9000 | 6000 | 7000 | 9000 | 10100 |

| Width (W) | mm | 2300 | 2300 | 2400 | 2400 | 2400 | 2400 |

| Height (H) | mm | 3200 | 3200 | 3400 | 3400 | 3400 | 3400 |

Common

Accessories

CONTROLLER

OPTIONS

CROWNING

SYSTEMS

BACKGAUGE

AXIS OPTIONS

TOOL HOLDING

SYSTEMS

SAFETY

SYSTEMS

Optional

Accessories

Request a Quote

Get a Fast Response

Explore other cnc press brakes